What are the different types of poly skin material used in hairpieces?

Posted by Superhairpieces on Nov 09, 2022

Poly skin is one of the most popular base materials because it comes with a number of benefits. It makes attaching and cleaning hairpieces easier, it provides plenty of durability, and the ultra thin skin poly units like the HD111 and M1111 are known for being extremely natural-looking.

However, there are also different types of poly skin which can be confusing especially for newcomers to the world of non-surgical hair replacement. And so, in this blog, we will be taking a look at the four main types of poly used at Superhairpieces so you have a much better understanding of this popular base material. As a result, you will also be able to better determine what type of poly is best suited for your next system!

Clear Poly

Clear poly is pure polyurethane material and is most commonly used in our skin base hair systems. The hair, usually consisting of Indian Remy human hair with men’s toupee, is directly knotted onto the poly. It is then sealed off by more layers of clear poly.

As we stated in our blog of why hairpieces can’t be natural-looking and durable at the same time, the thinner the base, the more realistic it will look. Likewise, the thinner the clear poly material, the more natural-looking the overall system will look. This is why ultra thin poly hair systems such as the HD111 and M111, that have a base thickness of 3-4 mils, are extremely realistic, although they come at the cost of durability as they only last 4-6 weeks as a general estimate.

Conversely, the thicker the clear skin, the more durable it is while coming at the cost of a natural appearance. While it’s still considered a thin skin hairpiece, the M101 has a base thickness of 8 mils, which is why it can last as long as 3-6 months in comparison to the HD111 and M111 provided it is properly maintained and taken care of.

The following hair systems all make use of clear poly material:

- M111

- HD111

- M161

- M161V

- M162

- M101

- M108

- M118

- M121

- M158

- M159

- M100

- M104

Poly Painting

Poly painting is when clear poly is painted on lace material. In other words, layers of clear poly material are brushed onto the lace system to create a poly perimeter. The hair is first knotted directly onto the lace material before it is sealed off by the layers of poly.

The benefit of poly painting on a lace system is that it makes attachment with clips, tape, or glue, much easier without compromising the lace area. Attachment and removal with a lace system can be messy, but if clear poly material is used, the process is much cleaner and efficient. Additionally, the poly material protects the edges of the lace from being ripped off while being durable itself, the poly material provides more durability for the lace system as a whole.

The following hair systems all make use of poly painting:

- HD106XL

- M106

- M106L

- M110P

- M116

- M204

- PW106HD

Poly Coating

Poly coating is similar to poly painting in that it is mainly used as a perimeter on lace or monofilament systems, but with a few notable differences. For one, poly coating is the thickest poly skin material used on our hairpieces. In fact, it’s so thick, it almost feels like plastic. But as we mentioned, the thicker the poly material, the more durable it is, and systems that make use of poly coating will definitely have plenty of durability.

Another difference is that poly coating usually requires glass silk poly material, which will be explained in the next point. If you’re wondering why the poly coating is not clear like the other poly materials, it’s because of this glass silk material. The resulting poly coating material seals off the hair that is directly knotted onto the lace or monofilament material by being glued or stitched on. This gives an additional boost of durability to the unit.

The following hair systems all make use of poly coating:

- M102/M102 Basic

- M108

- M109

- M112

- M178

- M179

Glass Silk

The final type of poly skin material is glass silk. It is essentially clear poly painting but with a layer of ultra super fine silk mono in between the very thin layers. It is more durable than clear poly skin while remaining more natural-looking than the thicker poly coating. So essentially, it’s the intersecting point between the two to provide the best of both worlds.

The following hair systems all make use of glass silk:

- M159

- M107

It should be noted that the glass silk on the M107 is referred to as beveled edge poly. This technique involves glass silk being embedded in between the lace material and clear poly material.

Conclusion

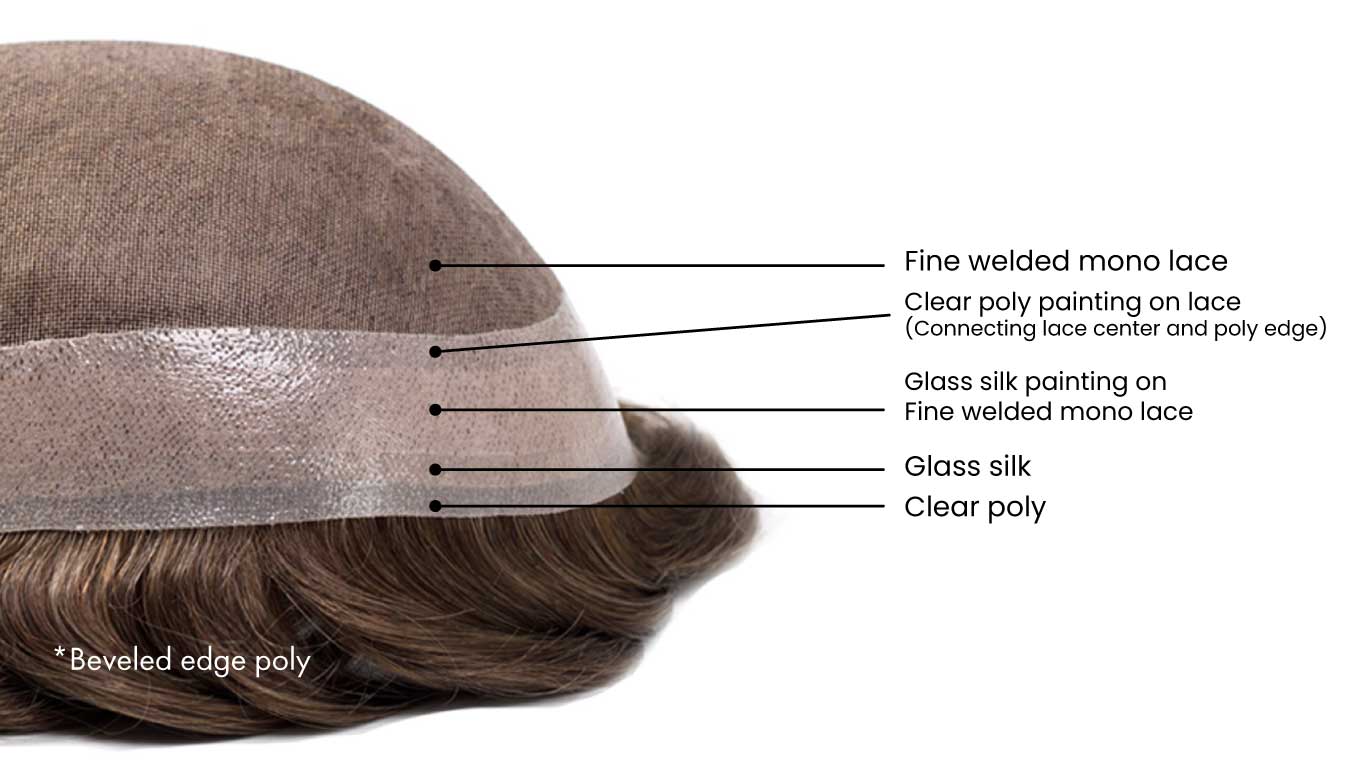

To give you a visual representation of these different types of poly, you can refer to the following image of the M107 fine welded mono lace system:

You should now hopefully know about the different types of poly material which, in turn, will help you pick your next hairpiece much easier. In the end, it all comes down to whether durability is your main priority, or a natural look.

------------------------------------------

Interested in learning more about getting started with hair systems for men? Browse through our website at www.superhairpieces.com (US & International) or superhairpieces.ca (CAN)

Don’t forget to tag us at @Superhairpieces and #Superhairpieces on your social media channels to get a shoutout! And make sure to like us on Facebook, follow on Instagram and subscribe to our YouTube channel!

Likes

Likes

USD

USD